Noise abatement has been the bane of workers for generations – particularly in the rapidly urbanised world we live in today. But one solution which has helped make noise complaints a thing of the past for contractors across numerous industries is Echo Barrier.

Here, we look at the story of how the market leader helped change the game when it comes to noise abatement – and has become trusted by corporations the world over.

Before Echo Barrier

The history of noise abatement dates back hundreds – if not thousands – of years. But while noise has always been a nuisance, the importance of combatting it to protect a business from prosecution and to prevent harm to people’s health is a relatively modern development.

Fixed barriers made from heavy duty materials like concrete and steel became more popular in the mid 20th century – particularly surrounding busy motorways and airports. But the need for regular upkeep makes them problematic.

But what makes them even more troublesome is that they aren’t suitable for temporary projects. And that’s especially important in a world where construction is on the up, particularly in urban areas where projects are placed in the heart of heavily populated areas.

Contractors turned to old fashioned solutions like thick blankets to dampen noise, although these too were not free from problems. For a start, they weren’t durable – and should they absorb water, make them much more difficult to handle and relocate.

While the technology behind fabric noise abatement materials has advanced since the 20th century, no temporary solution came close until the arrival of a new product to market in 2010.

How Echo Barrier changed the game

A group of acoustic experts – including internationally-renowned engineer Dr Peter Wilson – identified a gap in the market for temporary acoustic solutions which were effective enough to protect people from harmful levels of sound.

There was a growing demand from contractors across numerous industries for a solution that would protect their projects from delays, shutdowns or lofty fines. And their prayers were answered with Echo Barrier.

The team’s aim was a complicated one. To create an acoustic panel lightweight enough that it could easily be carried and installed by one worker, while still delivering the highest possible levels of noise reduction. Not only that, but it also had to withstand the elements, be fire resistant and simple to store and transport.

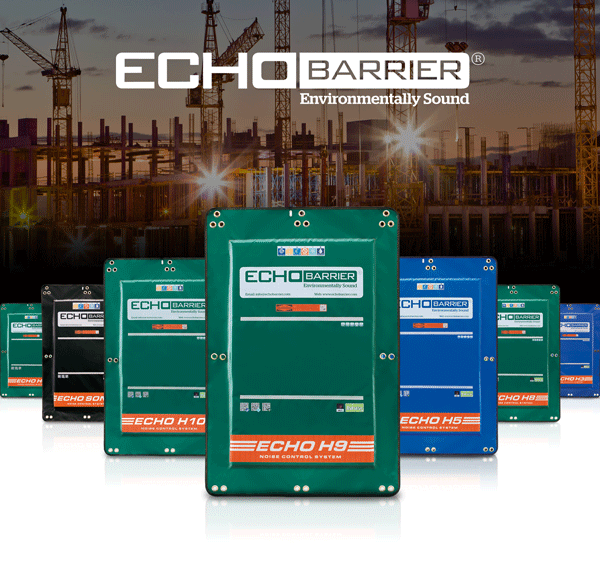

The multi-layered barrier they created – now seen across our H-Series™ products – incorporates a high-tech acoustic composite made from recycled materials secured through super durable PVC, a waterproof membrane and a reinforced mesh.

The science behind them means the barriers can reduce sound energy by up to 99% at certain frequencies and has made them the market leader the world over. That includes on megaprojects from the One World Trade Center to the Elizabeth Line.

The business has earned a host of award wins too.

The team continues to innovate and identify new ways to meet the challenging demands of a rapidly expanding urban environment.

Click here to learn more about the industries we support and contact us today to start your quote.